Please enter the website title

Products

MC Super Thin Square Chucks

Hangzhou Chandox Tosun Import & Export company is a joint venture enterprise, it was built in 2005 and located in city of Hangzhou. It is a Chandox sales company in Mainland, We have certificated ISO9001-2015 quality and management system. We have over forty professional employees to serve our customers, we also have four sales offices located in Shenyang, Yantai, Chongqing and Donguan.

Product Details

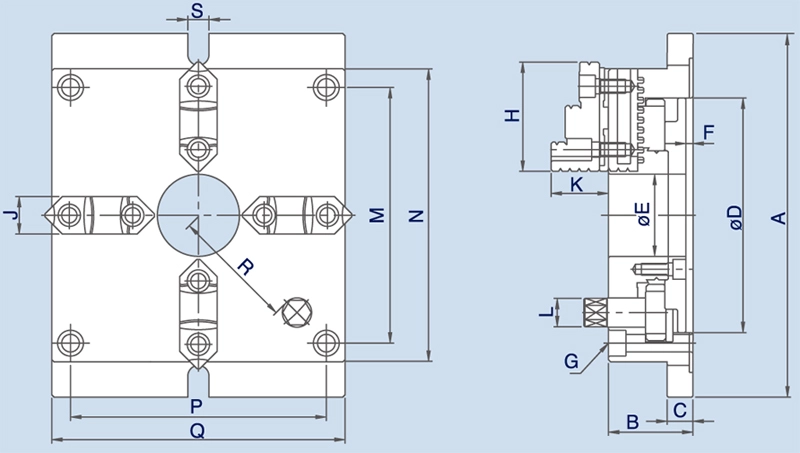

Dimension diagram

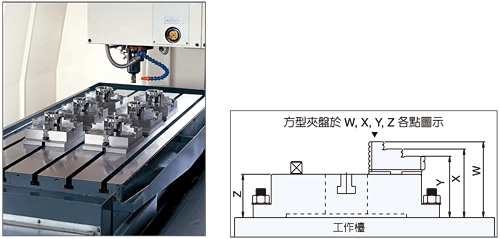

1.MC chucks are precisely ground, the tolerances of W,X,Y,Z among chucks are within 0.05mm.

2.Soft jaws can be used alternatively for machining special shaped work pieces, to substitute for designing and making a lot of jigs for this purpose.

3.The repetitive gripping accuracy with the hard jaws are within 0.02mm.

4.Parallel gripping accuracy with hard jaws can be controlled within 0.05mm after aligning sides of chucks.

| MODEL /SPEC. | A | B | C | D | E | F | G | H | J | K | L | M |

| MC-06 | 215 | 57 | 18 | 130 | 440 | 5.5 | 4-M10x1.5P | 68 | 26 | 39 | 14 | 144 |

| MC-08 | 250 | 65 | 20 | 160 | 55 | 6 | 4-M12x1.75P | 82 | 28 | 43 | 17 | 174 |

| MC-10 | 310 | 72 | 22 | 200 | 70 | 6 | 4-M14x2P | 93 | 32 | 50 | 21 | 218 |

| MC-12 | 380 | 85 | 25 | 260 | 100 | 7 | 4-M16x2P | 118 | 40 | 56 | 23 | 274 |

| MODEL /SPEC. | N | P | Q | R | S | Max.Gripping Diameter | Weight (kg) | |||||

| O.D.Clamping (mm) | I.D.Clamping (mm) | |||||||||||

| MC-06 | 165 | 144 | 165 | 66 | 18 | φ4-φ128 | φ55-φ128 | 11.4 | ||||

| MC-08 | 200 | 174 | 200 | 83 | 18 | φ5-φ162 | φ62-φ162 | 18.6 | ||||

| MC-10 | 250 | 218 | 250 | 104 | 18 | φ6-φ200 | φ72-φ200 | 31.6 | ||||

| MC-12 | 310 | 274 | 310 | 135 | 22 | φ10-φ265 | φ90-φ265 | 56.6 | ||||

★ Reserve the right to modify spcifications

choose an area code