News

A Comprehensive Guide to Selecting the Right 2-Jaw High Speed Hollow Power Chucks for Your Applicati

When it comes to precision machining, selecting the right chuck for your application is crucial. In this blog, we will focus on 2-Jaw High Speed Hollow Power Chucks and provide you with a comprehensive guide on how to choose the perfect chuck for your specific needs.

I. Understanding 2-Jaw High Speed Hollow Power Chucks

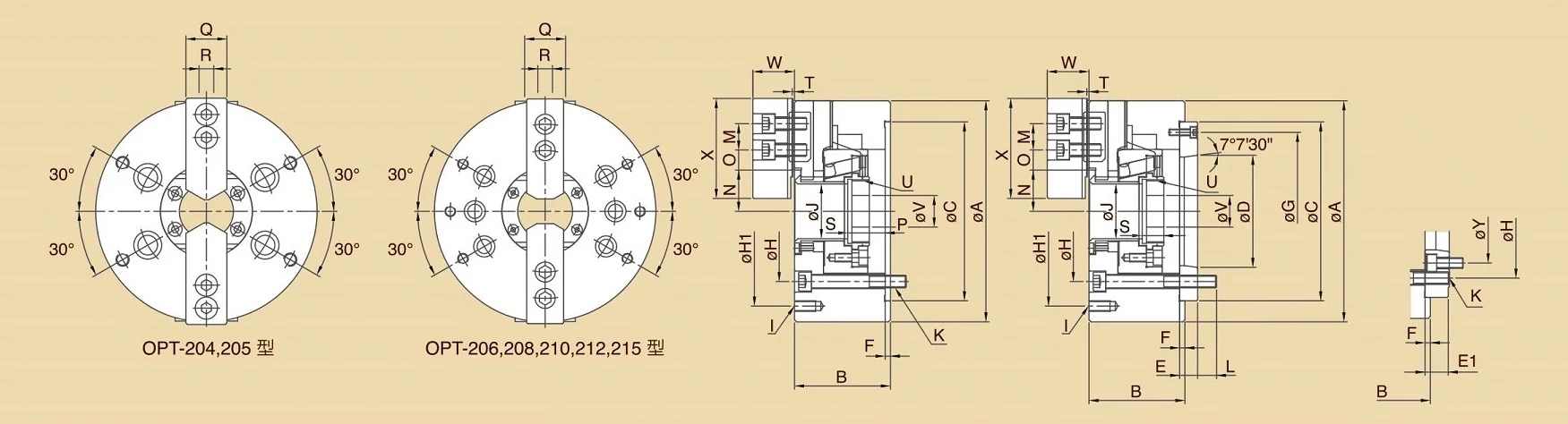

Before we dive into the selection process, let's first understand what 2-Jaw High Speed Hollow Power Chucks are and how they work. These chucks are designed to securely hold cylindrical workpieces during machining operations. They consist of two jaws that move simultaneously to grip the workpiece, providing stability and accuracy. The hollow design allows for the passage of bar stock or other long workpieces through the center of the chuck.

II. Determining the Chuck Size

The chuck size is a crucial factor to consider when selecting a 2-Jaw High Speed Hollow Power Chuck. It should be compatible with the size of your workpiece. Measure the diameter of your workpiece accurately and choose a chuck size that can accommodate it. It is recommended to select a chuck size slightly larger than the workpiece diameter to ensure a secure grip.

III. Evaluating Gripping Force

Gripping force is another critical consideration. It determines how securely the chuck holds the workpiece during machining. Insufficient gripping force can lead to slippage and inaccuracies, while excessive force can damage the workpiece. Calculate the required gripping force based on the material and weight of your workpiece. Ensure that the selected chuck can provide adequate gripping force to handle your specific application.

IV. Material Compatibility

Different materials require different chuck materials to ensure optimal performance. Consider the material of your workpiece and choose a chuck made from a compatible material. Common materials used for 2-Jaw High Speed Hollow Power Chucks include steel, cast iron, and aluminum. Each material has its own advantages and limitations, so select the one that suits your application requirements.

V. Additional Features

Modern 2-Jaw High Speed Hollow Power Chucks come with various additional features that can enhance productivity and ease of use. Let's explore some of these features:

1. Quick-Change Jaws: Some chucks offer quick-change jaw systems, allowing for easy and efficient jaw replacement. This feature is particularly useful when working with different workpiece sizes or when frequent jaw changes are required.

2. Self-Centering Capability: Certain chucks have self-centering capabilities, which means that the jaws automatically center the workpiece during clamping. This feature eliminates the need for manual centering, saving time and improving accuracy.

3. Coolant-Through Design: Chucks with a coolant-through design allow for the passage of coolant or cutting fluid through the chuck, directly to the cutting zone. This feature helps in maintaining temperature control and chip evacuation, resulting in improved machining performance.

Evaluate your specific needs and determine which additional features are essential for your application. Keep in mind that additional features may affect the overall cost of the chuck.

VI. Considering Accuracy and Repeatability

Precision machining requires high accuracy and repeatability. When selecting a 2-Jaw High Speed Hollow Power Chuck, consider its accuracy and repeatability specifications. Look for chucks that offer tight tolerances and consistent gripping performance. This ensures that your workpieces are held securely and accurately throughout the machining process.

Conclusion

Selecting the right 2-Jaw High Speed Hollow Power Chucks for your application is crucial for achieving accurate and efficient machining results. Consider factors such as chuck size, gripping force, material compatibility, additional features, accuracy, and repeatability. By carefully evaluating these factors and consulting with experts if needed, you can ensure that you choose the perfect chuck for your specific machining requirements. Remember, investing time and effort in selecting the right chuck will ultimately lead to improved productivity and quality in your machining operations.

Optimizing Efficiency and Throughput with 2-Jaw High Speed Hollow Power Chucks

Related to recommend